What is Coupling in Pipe Fitting?

Coupling pipe fitting is a way to connect two pipes together. Coupling is a fitting that connects two pipes together, often in industries such as oil and gas. The coupling fitting can be used to join sections of pipe or make connections between different types of pipe. It can be done with a threaded or welded connection. A coupling may also refer to the male/female fittings that are used on garden hoses and other water supply line connections.

Materials For Making Couplings?

A pipe coupling is generally made using one of two materials: plastic or metal. Plastics come in many different types and some may be rated for use with either hot or cold water, while others are designated as being suitable only for waste systems where temperatures will not exceed 140 degrees Fahrenheit. All metal couplings are made from either steel, brass or copper and they should be used with water that is not under pressure because the fittings can crack if too much weight is placed on them due to high velocity flow of liquids.

What is The Correct Way To Install A Coupling?

The first step would be screwing on one end of the coupling onto each pipe with an adjustable wrench (or open-ended wrench), then tightening it down by turning it clockwise until it cannot be turned any more using your hand only. You may need an extra set of hands to hold the other end of the coupling while you tighten it.

For larger, heavier couplings which are too heavy for one person to turn, attach a piece of thick rope onto each coupling and tie them together with an overhand knot (first tying a loose figure-eight knot around both handles). This will make your job easier when you try to tighten the fittings by turning them in a clockwise motion.

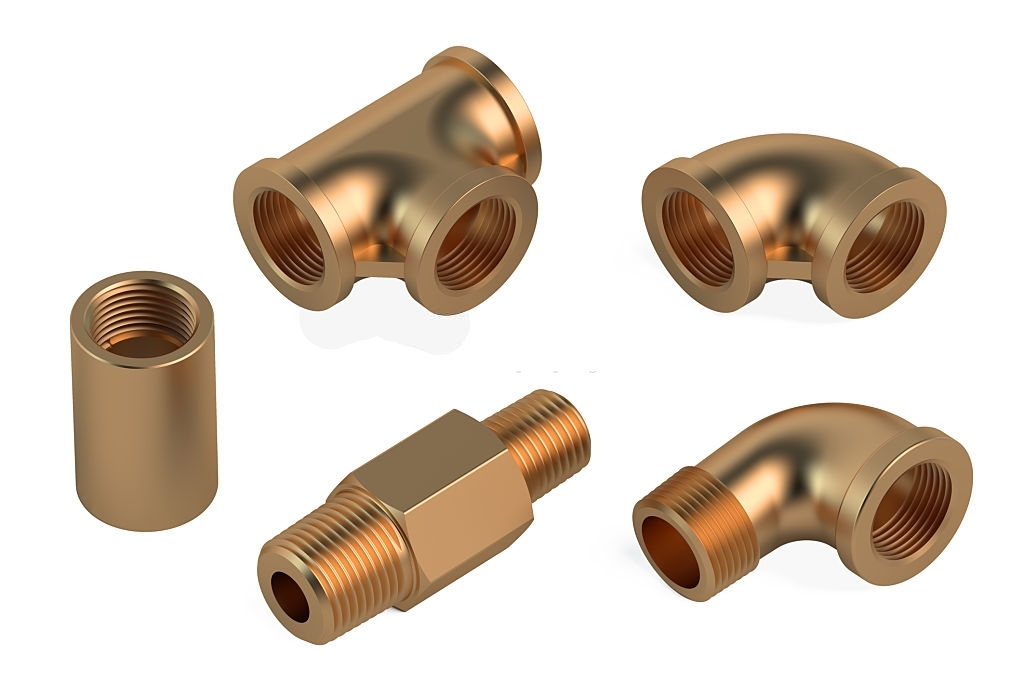

Different Types of Pipe Couplings?

A coupling is a pipe fitting that joins two pieces of pipe together. It can be from the same size all the way to very large sizes, such as those used in oil refineries and petrochemical plants. There are many different types of couplings available for use depending on your application needs. Some examples include but are not limited too:

Slip-on Coupling:

These couplings are used for joining two pieces of pipe together, the male end slides into the female.

Sock-it Coupling:

These couplings use a rubber "sock" to provide sealing between pipes. The coupling is slipped over both ends and then tightened down with bolts or screws using special tools.

Screwed Coupling:

These couplings use threads on the inside and outside of the female end. The male end has matching threads which are screwed together with a special wrench to create a seal between pipes.

Threaded Couplings:

These couplings have male and female ends that are threaded to thread together, PTFE tape or liquid joint compound can be used for sealing.

Tapered Coupling:

These are like metal bellows that expand from small to large diameters when two pieces of pipe with matching tapers are connected by screwing the coupling on tightly. The sealing is accomplished by applying liquid joint compound.

Long-Sweep Coupling:

These couplings are used on large diameter pipes to allow them to move and change without leaking. The fittings come in many different sizes and shapes, with the most common being a "t" shape fitting that allows for maximum movement of pipe while still sealing tightly.

Adapters:

This is a coupling that includes an adapter and two couplings. The adapter can be from the same size to much larger (such as in oil refineries). The purpose of this fitting is to provide access for repairs, etc., or add on parts such as valves.

Reducing Coupling :

A reducing coupling is one that can reduce the size of a pipe from say, ¾ inch to ½ inch. Reducing couplings are used in many applications such as venting and flaring systems, etc.

Expansion Coupling:

This is coupling which provides for expansion and contraction so that there will be no damage to your piping system due to thermal growth or contraction.

Grooved Coupling:

A grooved coupling is one that fits over the end of a pipe and has teeth or ridges inside which grip onto the outside diameter of another piece of piping for joining purposes.

What A Pipe Coupling Fitting Used For?

A pipe coupling fitting is used to connect two pipes or tubes together. There are many different types of couplings available and they can be installed in a number of ways, depending on the specific requirements. The most common type of piping connection is made using threaded fittings that screw into each end of the tube being joined. As illustrated above, there are also couplings that use clamps to attach the pipes together.

What is The Difference Between a Union And a Coupling?

A pipe coupling is a fitting that joins two pipes, while a union allows for the removal and replacement of components without shutting off water flow. A short length of pipe with male threads on each end is known as an NPT (National Pipe Thread Tapered) adapter. Couplings are more secure than unions because they have to be tightened down in order to be used. Unions are typically not as secure because they have a shorter length of pipe thread on each end. Couplings tend to cost more than unions, but that is only one difference between the two fittings.