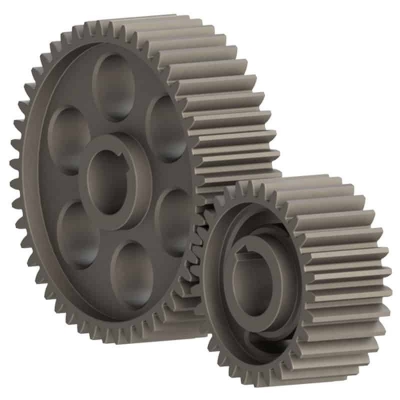

Spur

A spur gear is perhaps the most basic and widely employed gear. Spur gears also referred to as straight-cut gears, typically are constructed of cylinders or discs with axially protruding teeth. The teeth are particularly formed and not fully straight, and their function is to create a continuous driving ratio that is mainly involute but occasionally radial; the tip of the teeth is usually aligned to the rotational axis.

Spur gears have been used in manufacturing equipment to transmit mechanical force and control velocity, torque, and thrust. Several industry types of spur gear materials are used to construct a simple arrangement with flat, parallel teeth set around the perimeter of a cylinder body with a bore that slides atop shafts.

The flexibility of our precision forging spur gears tooth structure provides for great accuracy as well as easy manufacturing. Additional properties of spur gears are their absence of axial force which means the thrusting energy is parallel to the gear shaft, their high-speed and high-load capabilities, and their high-efficiency rates.

At Shacha Technoforge is the expert in spur gear forging and offers spur gears that are available mainly in two types: external and internal. External spur gear teeth are cut on the exterior surface of the cylinder that forms the gear. Two external gears mesh and spin in two different directions. The teeth of an internal gear are carved on the inside surface of its circular structure.

Spur Gear Application

-

Spur gears have a variety of applications, including increasing or decreasing the velocity of an item.

-

Spur gears could be used to raise or reduce a certain object's torque or power.

-

Spur gears are applied in mechanical systems to transmit speed and torque from one axis to the next. Spur gears are employed for this purpose in washers, blenders, dryers, heavy equipment, fuel injection, and factories.

-

Spur gears are used in power plants to transform a kind of energy, such as breeze or hydropower, into electrical energy.

-

Spur gears are frequently utilized in noise-free applications such as aircraft engines, railways, bicycles, ball mills, and crushers.

-

Automatic transmissions, conveyors, velocity controllers, engines, mechanically controlled transportation systems, gear pumps, diesel engines, and machine tools are examples of common industrial uses.