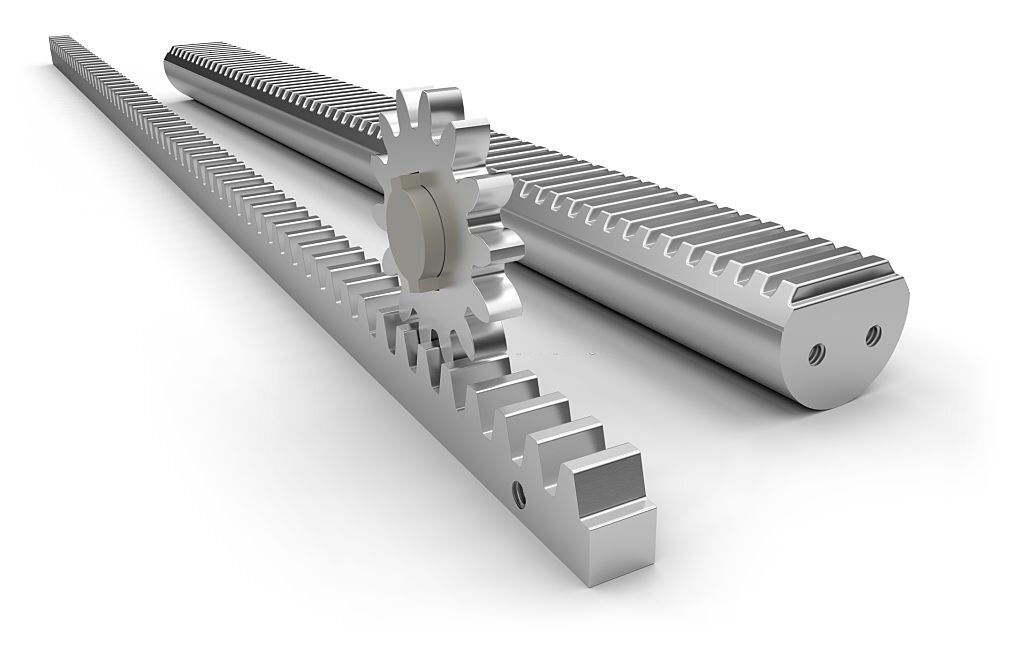

The working mechanisms of the small trucks, cars, and SUVs are unique, and so are the mechanical systems. The Rack and pinion set comprises a circular gear called pinion, and a linear gear called a rack. The basic working principle includes the conversion of a revolving motion into linear motion.

You will find this system in standard vehicles, small trucks, and also SUVs. The system is entirely different from the ball steering that is present in heavy-duty vehicles.

What is Rack and Pinion Gear?

In every vehicle, there is a mechanical system that controls the functions of the steering. In the case of the rack and pinion steering, the pinion’s rotation causes the rack’s linear motion. This will, in turn, rotate the wheels of the vehicles to the left or right.

Thus, the system is a common component of the railway’s mechanical system. The racks are present in between the rails of the trains. These interact with the pinions that remain attached to the train cars and locomotives. The rack and pinion gear aid in the upward movement of the trains across the steep inclines.

Simplifying the system

If you are discussing the needs with a premium Rack and pinion manufacturing company like Shacha Technoforge, you will get a simple explanation of the complicated system.

- It is primarily a gear that gets attached to the toothed bar.

- The bar is attached to the set of tie rods.

- The rack is a generating one. So it has an outline resembling the design of a generating tool, like a gear shape cutter or a hob. It indicates the dimensions and structural details.

The simple linear actuators usually possess a combination of rack and pinion. A motor or a hand provides the power for shaft rotation of the pinion that causes linear movement.

Advantages of the rack and pinion steering system

The standard mechanical steering and the rack and pinion steering gear are the two prime options that you have got while choosing the steering system. The recent rise in the demand for the rack and pinion system must have been owing to the several advantages of the system.

- The Rack and pinion industries can be very precise with the design of the steering set as there are fewer parts to deal with. The number of pivot points is also low. And it is the reason why the steering is more responsible and convenient to control.

- With the reduction in the number of parts of the steering system, there is a reduction in the weight too. A few pounds lesser will always aid in lesser fuel consumption.

- The quick and high-quality feedback will always aid in safer driving eve p the wet and icy roads.

- Repairs are easy for two reasons. Firstly, as it is a common system, most mechanics can handle it. Secondly. There are fewer moving parts which will already minimize the need for repairs.

But you should ideally work with the most reputed Rack and pinion company as the quality of the steering depends on the process of manufacturing too.

Application of rack and pinion

You can find the use of the rack and pinion gears in almost all types of modern-day vehicles.

It is time to learn about some other common applications from the discussion below.

-

Car Steering: As already discussed, the job of the rack and pinion steering gear is to convert the revolving motion into linear motion. If you check the small trucks, compact SUVs, and most other cars, you will find the presence of the steering system as a common feature. It aids in better control of the tire movement with the steering wheel.

-

Railways: have you ever wondered how the trains are moving across the mountainous terrains? The rack and pinion gear are responsible for the movement on the steep gradients, up to 45 degrees.

The rack railways build a rack into the center of the tracks and have the pinions on the locomotives. It will be the safest option for upward movement instead of relying on the friction factor alone, as in the traditional railways. Moreover, there are controlled brakes on these trains that will reduce the impact of ice or snow on the rails.

-

Stairlifts: let’s explain the mechanism of working of the stairlifts. The motor will turn the gear that remains in a mesh inside the gear strip present on the rail or track. When you turn the gear, the chair will move accordingly, along the strip with the gear. The moment will happen in one direction. So for reverse movement, you have to apply the reverse gear.

-

Actuators: perhaps one of the most interesting fields for the rack and pinion industries is the actuator. Actuators are the machines responsible for the movement of various components, like the pipeline transport system.

In such systems, the rack and pinion gear will aid in valve control and the basic functioning of the system.

More applications

Shacha Technoforge also manufactures the Bevel gear application, which are the instruments that axe the primary shafts with the cuts and the tooth-bearing portions of the gears. You can assemble the bevel gears on shafts with 90 degrees space between them.

The different type of bevel gear include

- Straight bevel gear

- Spiral bevel gear

- Zerol bevel gear

- Hypoid bevel gear

- Mitre gears

Now that you know about the Bevel gear Type, you can start looking for suitable oes at the reputed companies. We at Shacha Technoforge are manufacturing different types of Bevel gears Like Straight Bevel Gear, Spiral Bevel Gear, Zerol Bevel Gear, Hypoid Bevel Gear, and Miter Bevel gear.

A final word

The knowledge about the rack and pinion Uses will help you to decide whether you need the steering set. The common applications show you how these steering systems have become a vital part of many complex systems.

Rely on the companies that have been manufacturing these components for many years with a very good reputation in the market. You can get the best gears at Shacha Technoforge. Call the company if you need more information and clarifications.

Article Updated : August 22, 2022

Read More Article :

1. More Detail About Bevel Gear

For any query, contact us at info@shachatechnoforge.com / +91 97254 18623