Slip-On Flanges: What are they?

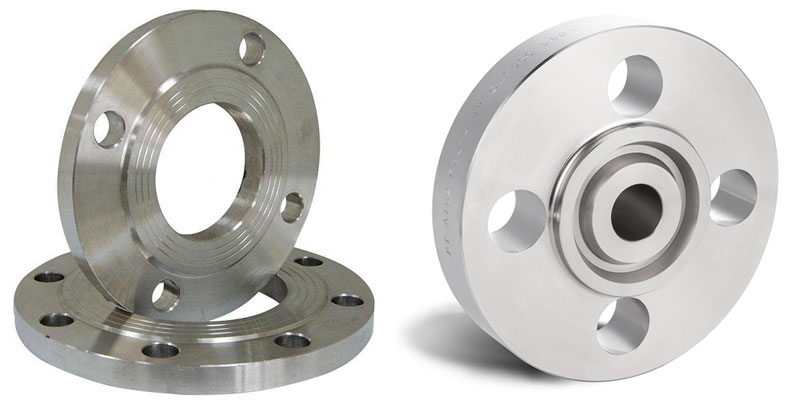

Slip-on flanges are also known as SO flanges. Slip on pipe flange is meant to fit over pipes and are hence designed somewhat larger than the pipe itself. It attaches to the pipe by fillet welding at the top and bottom of the flange. It is utilized to put the pipe through into the flange's circular bore; because the flange's internal diameter is slightly larger as compared to the pipe's external diameter, the pipe and flange may be joined by a lap weld at the top and bottom of the flanges.

This flange is simply a ring that is fitted over the pipe's end, with the flange facing protruded far enough from the pipe's end, which makes it convenient for slip on flange welding and allows for welding beads to be applied on the inner diameter.

At the rear end of the flange, the OD of the slip-on flange is likewise fused. Slip-on flanges are less expensive and are relatively easier to align, making them a perfect choice for the intended application. Though depending upon the application there are different types of Slip On flanges made available by the manufacturer and ShachaTechnoforge has risen up among the ranks as the best manufacturer when comes to Slip on flanges.

Types of Slip on Flanges

Slip-on flanges come in a variety of shapes and sizes, such as the

-

Reducing Slip On Flange

These flanges are frequently utilized pipe-to-pipe couplings and are offered in various sorts and pressure grades. The decreasing flange consists of a flange with a bore of a separate and narrower width than the flange. Aside from the core and ring specifications, the decreasing flange will have bigger pipe diameter variables. Slip on flange welds are employed to expand the joint's discharge end to enhance the flange size. This is the most cost-effective way to change sizes in a piping network.

-

Raised Face Slip On Flange

The raised face is designed to reduce the contact area of the gasket, focusing on the surface pressure being exerted once the flange is welded. As a consequence, the seal is powerful. Raised face slip on flanges is employed to terminate the end of the piping system or valve. The raised face is designed to absorb more force on a relatively small area of the flange, allowing for greater control at elevated pressures. It is required to weld slip on the flange to the pipe.

-

RTJ Slip On Flange

A tiny grooved is carved on the raised face portion, this kind is termed RTJ SO flange type, the purpose of this slot is to install the gasket's rim, also used for caulking, RTJ is intended for high-pressure usage. Ring-type Joint slip-on Flanges are traditionally utilized in high-pressure and high-temperature applications, whereas Carbon Steel Ring-type Joint Flanges are leakproof. Here too, Slip on flange welding is required.

When do We Use Slip On Flange?

Slip-on flanges are most commonly used with low-pressure liquids. Furthermore, the flanges function efficiently with minimal possibility of spillage. These flanges are ideal for use in cooling water lines, firefighting water lines, and low-pressure pressurized aviation lines. Slip-on flanges are also used in production lines to ensure the flow of vapor, oil, gasoline, distillates, and so on. These flanges are suitable for systems with lower pressures and extreme temperatures.

The flange is useful for lessening line width and limiting space constraints. These flanges are used in conjunction with the Slip-on weld flange and reducer pair. They are beneficial whenever the movement in the piping system is channeled from one size to another. The internal and external welded slip-on flanges provide them with the capacity to avoid leaks as well as the necessary durability.

Limitations of Slip on Flanges:

Though one of the most functional and essential flange arrangements available, Slip on flanges suffer from their own set of limitations. Limitations for Slip on Flanges relate to:

• It is not being able to endure cyclic stress.

• It results in a dramatic reduction of mechanical strength

• More often it necessitates 2 welds rather than being operational with just one

• Some non-destructive testing on welds is not possible.

• In ASME class 1500, 2.5-inch and larger sizes are not attainable.

• ASME class 2500 is not found in all sizes.

• Above ASME class 600, it is often not utilized.

However, as or when the slip on flanges are limited, as a manufacturer and supplier, we offer a variety of other flanges to function in place of this.

We Also Manufacturer Different Flanges

At ShachaTechnoforge, though our Slip on flanges are perfect and the best in terms of specifications and gradings our other flanges do not lag behind either. As a prominent flanges manufacturer, we have been effectively addressing the ever-increasing market for flanges with a technologically advanced production infrastructure and top-of-the-line raw material utilization. Apart from being a major manufacturer and supplier of Slip on flange, other flanges that we offer from our product line are:

• Weld Neck Flange

• Blind Flange

• Socket Weld/ Counter Bore Flange

• Threaded/ Companion Flange

• Lap Joint Flange

Why ShachaTechnoforge Should be Your First Choice for Slip-on Forge?

In the fabrication and forging of world-class flanges, ShachaTechnoforge is ISO 9001: 2015 and CE-recognized. ShachaTechnoforge has consistently forged and supplied best-in-class flanges for a wide range of industries and purposes. Its main purpose is to join pipes, siphons, valves, and other devices to construct a channeling framework. These flanges allow anyone to easily repair and preserve the line structure.

If you desire the finest quality flanges, ShachaTechnoforge should be your first choice, sinceShachaTechnoforge adheres to the stringent international and nationwide dimensions, as much as any additional criteria that the customer specifies, making us more functional and more convenient to choose.