Sacha Technoforge is one of the reputed Bevel Gear forging companies in Gujarat. The proposed equipment is extensively used in a variety of kinds of industrial and mechanical operations; it gives low noise operation and clean function. We are a well-recognized provider of bevel gears in Gujarat and additionally supply helical gears and spur gears. This Gear forging company is best for use in transmitting strength between shafts that are usually positioned at 90° to every other. Our particular engineering offers the best overall performance underneath traumatic conditions.

Shacha Technoforge is the leading Bevel Gear manufacturer. Recommended equipment is regularly set up on a shaft at ninety levels however can be designed to function at any different angle. Our variety is additionally handy in customized choices as per the needs of our esteemed clients. We grant these bevel gears in Gujarat with terrific features. They are manufactured with the most advantageous fine substances as per set enterprise standards.

We are a trusted Bevel Gear Exporter in India. Designed using modern technology and techniques, our collection is widely appreciated in various industries for its features such as precision engineering, rigid construction, and high tensile strength. If you are looking for a Gear forging company in Gujarat then you can contact us directly.

Forged Bevel Gear Manufacturing Company In Gujarat

Gears are gadgets made of toothed wheels that transmit mechanical electricity between two components. Bevel gears manufacturers are typically employed in machines engaged in multi-industrial processes, such as force structures and manufacturing lines, however additionally in quite a several sectors such as aeronautics, mining, textiles, or pharmaceuticals.

What Is Bevel Gear?

Bevel gears are power transmission parts that are primarily employed to change the direction of shaft rotation and reduce speed and improve torque between non-parallel spinning shafts. They are used on shafts with intersecting axes and, in particular, on shaft problems whose axes do not intersect.

The shaft is always, but not presently, perpendicular. Shacha Technoforge is a Leading Bevel Gear manufacturer that can be classified by the shape of its teeth, either curved or straight. Bevel gears are explained here, along with a discussion of their function and typical applications.

Bevel gears are those that use two beveled toothed wheels to transfer power between axes cut in the same space; However, gear forging companies can use hypoid gears to transfer power between two axes.

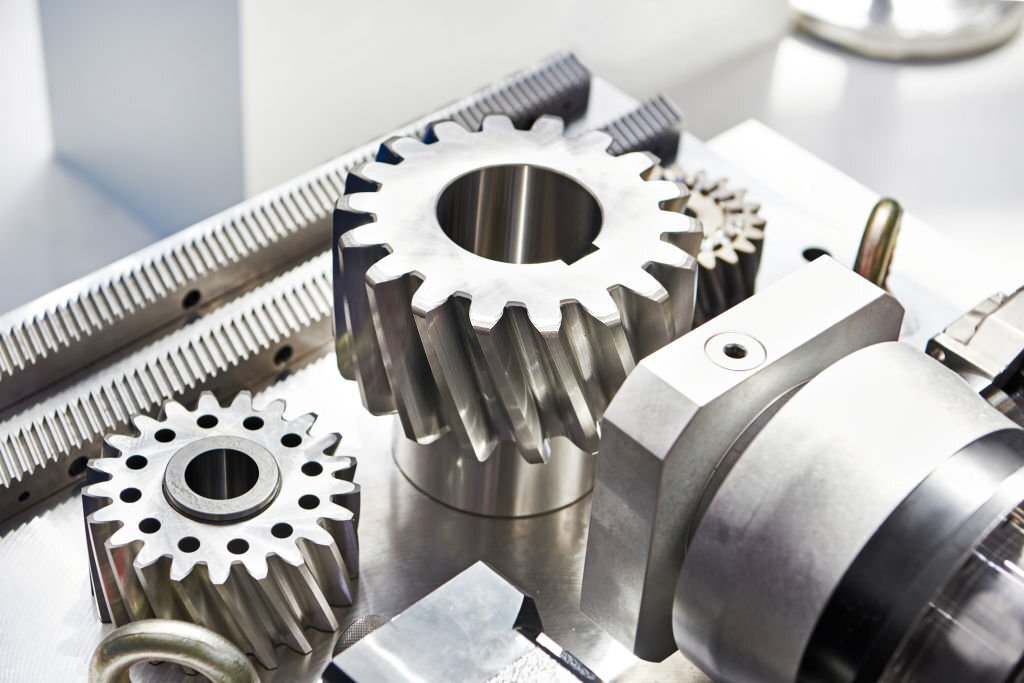

The teeth of a bevel gear can be either straight or spiral, also known as a conical helix. Different types of gears can be classified based on their tooth width, but also tooth face width or center circular pitch.

Different types of highest Quality Bevel Gears

Shacha Technoforge manufactures different types of Bevel gears such as Straight Bevel Gear, Spiral Bevel Gear, Zerol Bevel Gear, Hypoid Bevel Gear, and Miter Bevel gear. Bevel gear application is the simplest and most effective method of changing the axis of rotation of the drivetrain. The type of bevel gear and the manufacturing processes used to depend on the type of application. Mainly Bevel Gear is Used for changing the direction of rotation by 90 degrees, bevel gears have a lot of applications.

-

Spiral Bevel Gear

These bevel gears have the specialty of working in very steep and different planes. Their meshing sets them apart since the pinion teeth are wider than the main gear. This makes it easier for them to transfer very high torques without wear, since the teeth of the pinion mesh with the various teeth of the main gear. We, the Bevel Gear forging supplier, have teeth that are curved and slanted, as opposed to the tooth orientation of straight bevel gears. This results in more overlap between the teeth, which promotes gradual engagement and disengagement of the tooth contacts.

-

Zerol Bevel Gear

Bevel gear teeth are curved lengthwise. These gears are somewhat similar to spiral bevel gears in their profile. Their difference is the spiral angle; the Zerole type has a spiral angle of 0°, while the spiral type has 35°. As with straight bevel gears, gerrol types do not produce additional thrust loads.

Thus, plain contact bearings can be used. Gear types can be replaced with straight bevel gears without changing housing or bearings. Furthermore, due to their curvature, the teeth of roll bevel gears have a slightly overlapping action similar to that of spiral gears.

-

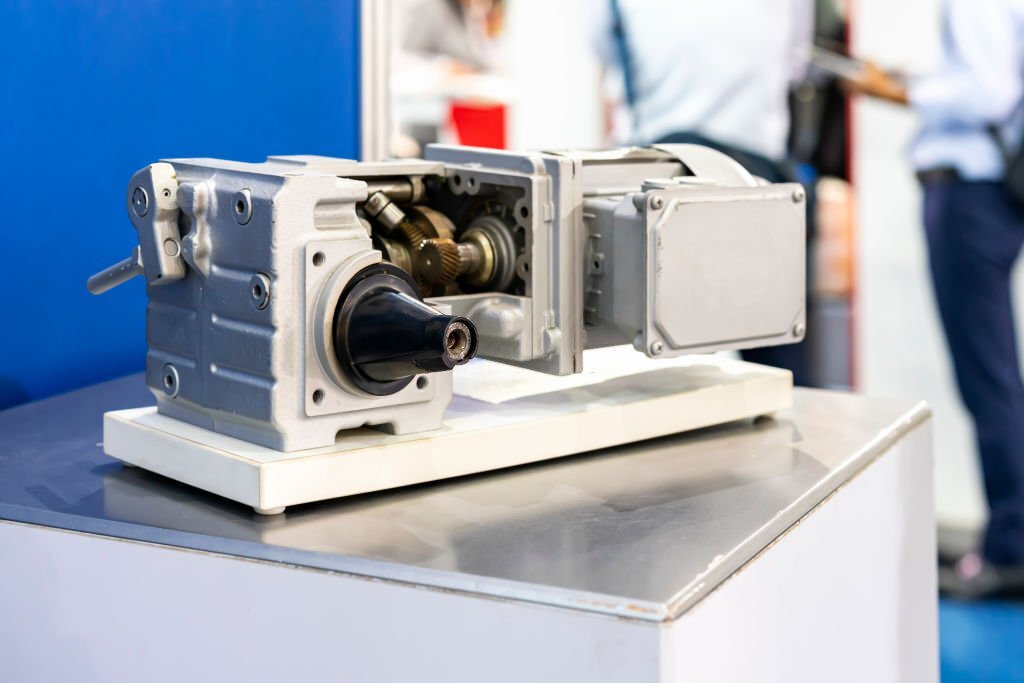

Hypoid Bevel Gear

Hypoid bevel equipment is a distinctive kind of bevel equipment in which the shaft axes are neither intersecting nor parallel. The distance between two equipment axes is known as the offset. Hypoid bevel tools enamel is helical, comparable to spiral bevel gears. A hypoid bevel tool designed with no offset is truly a spiral bevel gear. The manufacture and structure of the hypoid kind are comparable to that of the spiral bevel gear.

-

Straight Bevel Gear

Straight bevel equipment is the easiest shape of a bevel gear. The enamel is in a straight line that intersects the axis of the equipment when extended. The tooth emerges as shorter in thickness, making the outer section or heel of the enamel larger than the internal phase or toe. Straight bevel gears have on-the-spot contact lines, allowing larger tolerances in mounting.

-

Miter Bevel Gear

It is a kind of bevel tool with an equipment ratio of 1:1, which means that the driver and pushed gears have an identical quantity of teeth. Since a meter tool does not create any mechanical advantage, this kind of work is confined to adjustments in axis or rotation. Typically, meter gears have axes that intersect perpendicularly. the shafts are aligned to intersect at any angle in some assemblies.

Bevel gears are rotating desktop aspects used to transmit mechanical electricity between two intersecting shafts, both perpendicular or at an angle. Besides altering the axis of rotation, bevel gears can additionally create a mechanical benefit by way of growing the output torque. We are the best bevel gear manufacturer, and manufacturing mechanical facility. These gears can also be used as a speed reduction mechanism.

Article Updated : August 2 , 2022

Read More Articles:

1. Different type of Pipe Fitting Product