ShachaTechnoforge is india’s leading stainless steel flanges manufacturer and supplier In the business since 2014, ShachaTechnoforgehas been viewed as the most encouraging accomplice for a variety ofclientelein fields such as Agriculture, Pipe fittings, Railway, Refinery, Automobiles etc. Based out of the Industrial hub in the major modern district of Gujarat we have been maintaining our business tasks easily in domestic as well as in the global arena and in a short span of time we have proven out mettle. Our offered range including Gears, Metal Flanges, Stainless Steel Flanges, Pipe Fittinghave earned a reputation for its unrivaled quality. Additionally, we have our sharp awareness towards keeping up manageability in the business. We try to be the most trusted and favored provider of forged items with top notch characteristics. Our company is resolved to innovate and advance in its product development and a responsiblecare for social and ecological well-being with continuous improvement zeroed in on the manageable advancement of the business. ShachaTechnoforge is ISO 9001: 2015 certified in the manufacture and forging of world class Flanges. The establishment of our business legacy marches on as it is based on our founding principles of quality, client support and execution.

Our infrastructure consists of Close Die Forging Unit with Forging machinery suitable for job capacity ranging from 5kg to 50kg. Our CNC & VMC machining units processes the transformation of raw material to different desired shapes. Our world class laboratory is equipped to constantly meet the standards and facilitates our research to come up with more innovative operations.

What is a Flange?

Flanges are a type of fitting that is used in pipe and tubing systems. It's often used in metalworking and engineering for joining pipes, valves, pumps and other equipment together so that they can work smoothly as one unit. They offer the advantages of being able to connect different types of materials together, while also allowing flexibility for when components need to be removed or replaced. A flange can have female ends (such as on a steel beam) where it would receive bolts from another component, or male ends (such as on a steel pipe) where it would connect to another component.

What are Flanges Used For?

To reduce pressure or strain exerted on pipelines without reducing fluid flow rate - Connecting large diameter piping systems together in power plants, refineries, chemical plants - To connect and disconnect piping systems

Facilitating repairs in pipelines by making it easier to access them (e.g., when an emergency shutdown is required) or relocating a pipeline

Materials for Flanges

Our Flanges are forged in various materials like Stainless Steel, Alloy, Carbon and have machined surfaces. The material of a Flange, is essentially set in accordance with the choice of the pipe, and as a rule, a Flange is of a similar material as the pipe in use. All of our Flanges material and product range, fall under the IS, ASTM, JIS, DIN, IS and other international standards norms. Each product depending on the material portrays distinct measurements, dimensional resilience and material characteristics.

Types of Flanges

Their are many different types of flanges are determined by their shape, thickness and other properties. We manufacture 6 different kinds of forged steel flanges. get more details about each type below:

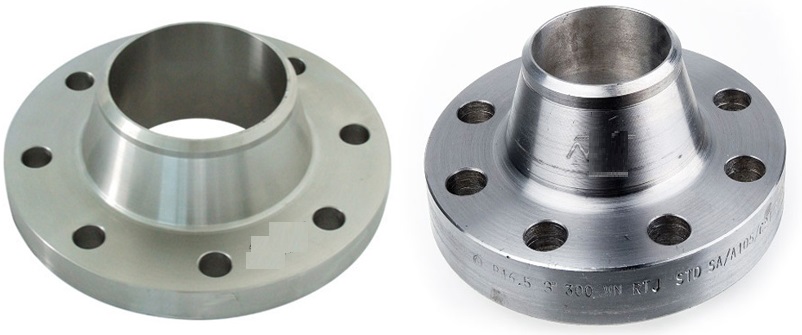

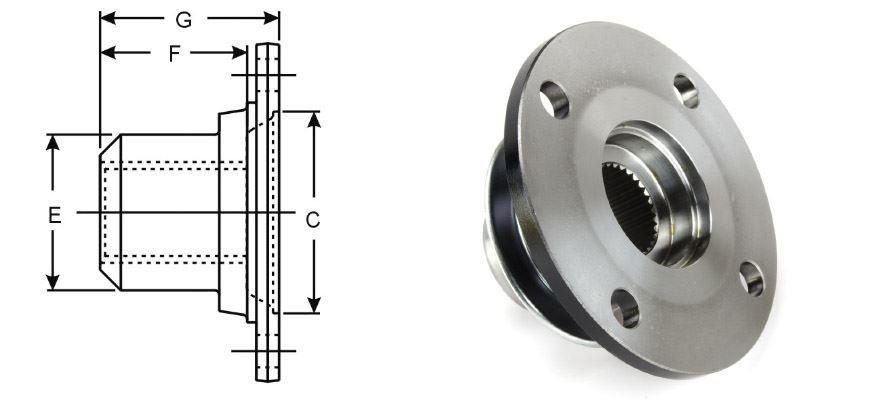

1. Welding Neck Flanges:

Our Stainless Steel Welding Neck Flanges have long tapered core that goes steadily over to the barrier width from a pipe or fitting. The long tapered hub provides an important reinforcement for use in several applications involving high pressure, sub-zero and / or elevated temperatures. These Weld Neck flanges are ribbedto match the inside diameter of the mating pipe or fitting so there will be no restriction of product flow. This forestalls disturbance at the joint and decreases disintegration. They additionally give phenomenal pressure conveyance through the tightened center and are effectively monitored for flaws, if any.

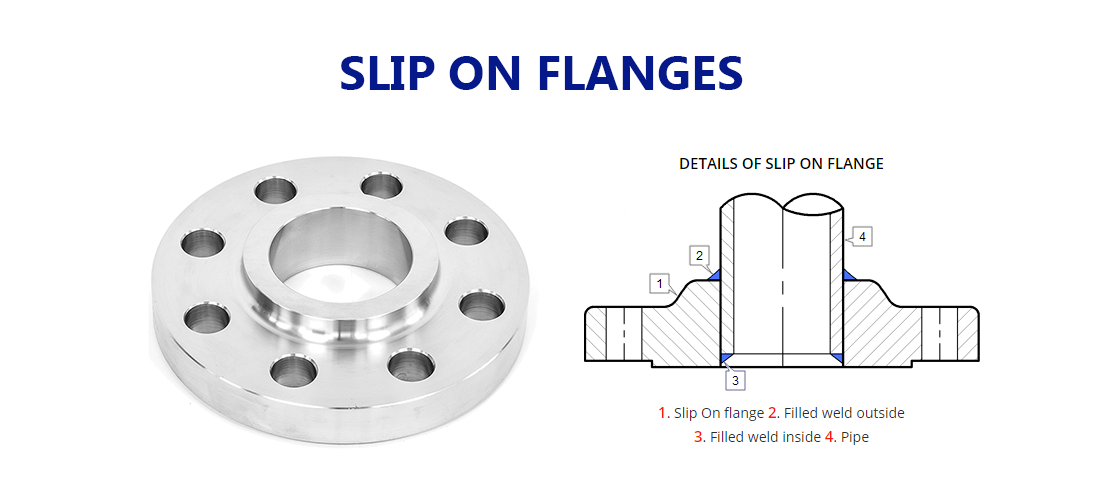

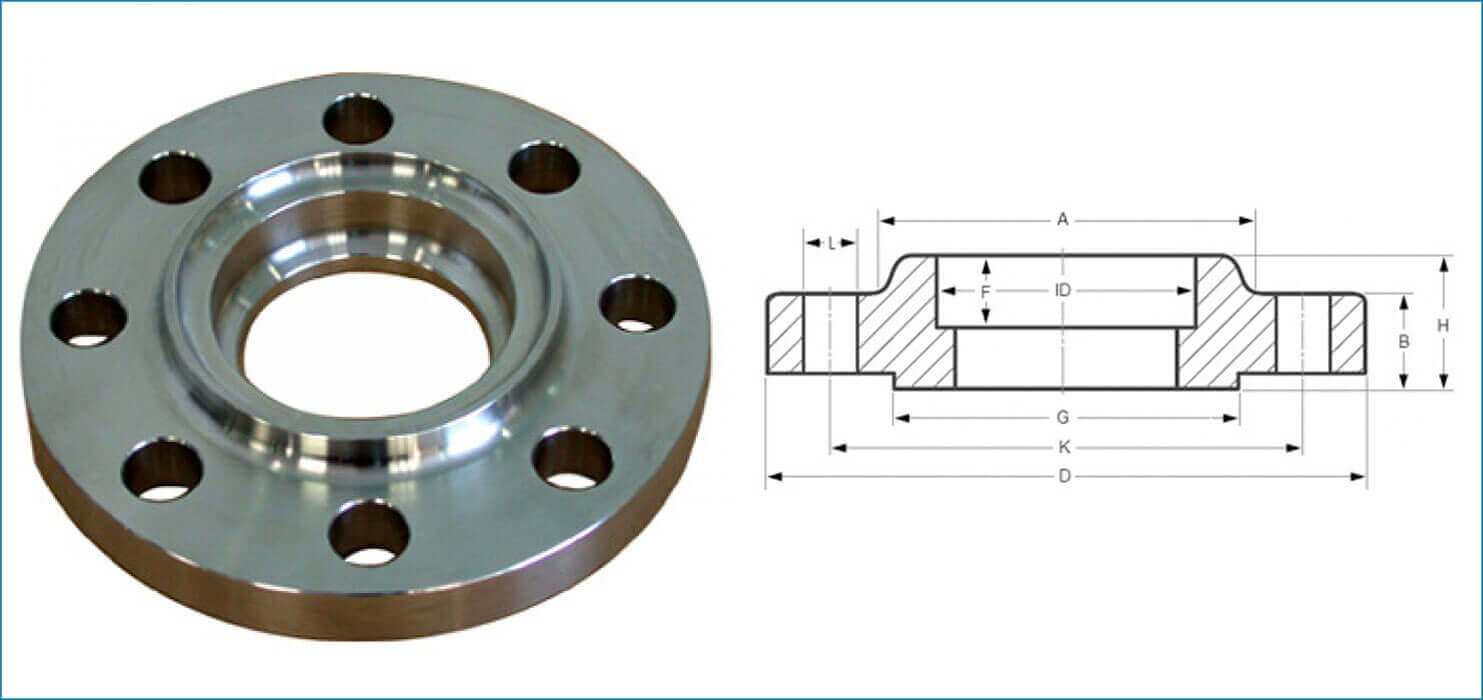

2. Slip on Flanges:

Our SS Slip on Flanges are easy to install and thus the most wide spread application of it, along with the low material costing. These flanges may also act as a replacement for Lap Joint Flanges. Slip On Flange is essentially a ring that is placed over the pipe end, with the Flange face extending from the end of the pipe by enough distance to apply a weld bead on the inside diameter. Our product is the perfect choice when it comes to usage for fluids at low pressure and with little to no risk of leakage.

3. Socket Weld/Counter Bore Flanges:

Our Steel Socket Weld flanges are perfect for use on small-size high pressure piping system. Their static strength is equal to Slip On flanges, but their weariness strength is 50% more than double-welded Slip On flanges. The shoulder of the flange acts as a point to set the depth of the pipe which is inserted into theSocket Weld flange.

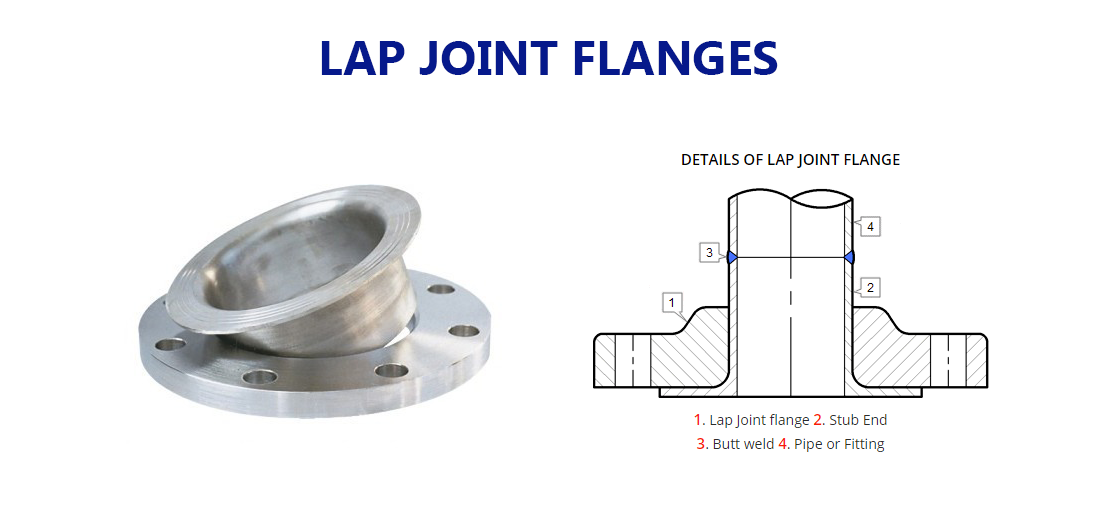

4. Lap Joint Flanges:

Our Stainless Steel Lap Joint Flanges are the type of flanges which are particularly useful for large or difficult to adjust flanges. It is a assembly type flange with two components. It has a stub end with a ring to which a flange is placed over. This end is then welded to the pipe, and the ring can be turned to line up with the mating flange. Our Lap Joint Flanges are usually used in low pressure application with little load resilience.

5. Threaded/ Companion Flanges:

Our SS Threaded Flanges also known as Companion Flanges are specially forged to be attached to the pipe without needing to be welded. These flanges are threaded or has a socket like make in its bore and are a perfect match to the threads on the external side of a pipe. Threaded Flanges are similar to the Slip On Flanges. Because of its No weld application it can be used easily and are used for a smaller diameter and often for a high pressure requirement.

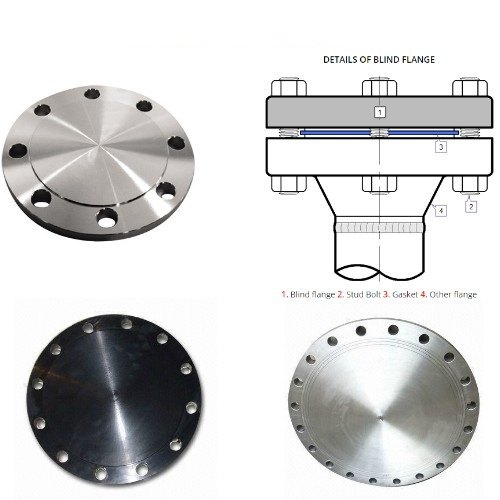

6. Blind Flanges:

Our Steel Blind Flanges are similar to any flanges thickness or bolting pattern but does not have a bored center. The purpose of Blind flanges is to act as block off for pipes or nozzle that is not used. It is mostly used at the end of a piping network. It is built to withstand high pressure.

More FAQ's Abour Our Flanges Products

What Are The Advantages of Flanges?

Flanges have a number of advantages for different industries, from oil and gas to automotive. The advantage they offer is the possibility of an easy connection between two different pieces or parts that are not necessarily in direct contact with one another. They can be used as connectors due to their quality construction which ensures durability over time. One example of how flanges are used in the modern world is to connect a piping system with the best possible seal.

Is Flange a Fitting?

Flanges are often mistaken as fittings, but they are not. Flanges come in a variety of types and sizes like any other fitting does. They have the same basic function to connect two pipes or components together securely. The difference is that flanges sit on top of the pipe while creating this connection whereas a fitting sits inside the pipe and creates a tight seal. A flange is made up of two components: the face and the gasket, which helps to create a watertight connection between pipes.

What is a Male Flange?

A male flange is a raised surface that fits into the opening of another object. This means it can be used to connect pipes, valves and other equipment together with screws or bolts. A Male Flange may also have pipe inserts which are then secured in place by tightening nuts on either side of the flange . The use of a male flange is to create a seal between two objects.

Male flanges are sometimes referred to as "flat flanges" because they have little depth, although there are also deep-drawn male flanges that extend below the plane of the connecting surfaces . These may be used for pressure purposes or simply due to design preference . Male Flanges come in different sizes and shapes to accommodate a range of connections.

What is a Female Flange?

A female flange is the opposite of a male flange; it has an opening where other objects can fit into, rather than having any kind of raised surface . This means that bolts or screws are used to hold two pieces together instead of the flange itself creating a seal between them. Female Flanges are also sometimes referred to as "flanged fittings" or simply plain "flanges".

A female flange is used when it's important that the connection can easily be disassembled and removed . This may include changes to existing systems, repairs or upgrades . A female flange does not always need to be attached to a raised surface like the male flange. It can simply connect two objects together .

Females are made in many different shapes and sizes, depending on what they will be used for. For example, an elbow female flange is commonly found at 90 degree angles because this allows it to fit into a corner of two surfaces.

Why Do Flanges Have a Raised Face?

A flange is a raised face that allows for quick and easy coupling of two objects. Flanges are typically used in the piping industry to connect pipes or fitting together with fasteners so that they can be securely connected using not just one joint, but rather several joints. This type of connection provides added stability when it comes to high pressure applications, which require a secure connection to be maintained.

What Is an Adapter Flange?

An adapter flange is the type of flanges that converts one size into another, and also called as reducer or sleeve coupling. This means when you have two different sizes or types, this product will help you connect them together so it can be used. These are mostly used in high pressure systems, and the flange allows for different types of piping to be joined together seamlessly.

An adapter Flange is Adapted Coupling which can connect two pipes with different outer diameters or wall thicknesses such as copper tube and steel pipe etc., Converts one size into another like reducing a large size to a small size etc.

What Is an Expansion Flange?

Expansion flanges are used in pipelines and vessels, the expansion flange can compensate for thermal growth which allows for increased stress tolerance than other type of flanges. A typical application is found when there needs to accommodate changes within temperature variations that may grow or shrink the piping, vessels or other equipment.

The expansion flange is used to prevent damage due to thermal growth of pipes and vessel that occurs when they are heated up or cooled down. It can make large variations in temperature between hot and cold water crossings with no problems for your pipeline.

How Do I Know What Flange I Have?

One of the most common questions we get is "How can I tell what size flange my appliance has?" The good news is that it's usually easy to find out. Flanges are typically labeled in three ways: with a series of letters and numbers, stamped into aluminum or steel plates on each side of the tank; by stamping or engraving the name or model of a flange directly on one side; and by attaching an identification tag to the appliance.

Is Flange a Standard?

Flange is a cylindrical device with an opening at one end. The flanges are designed to be attached to pipes and other tubing that require enhanced strength for connecting different pieces of equipment together, ensuring proper airtightness in the system, preventing leakage due to corrosion or heat stress among others reasons. They are machined from thin metal plates, and they can be attached to the pipe or tube by welding, bolting them on using bolts with their heads cut off

Our Range Of Steel Flanges

We are leading flanges manufacturers and we offer our flanges in a wide variety and different dimensional size ranging from ½” to 24” with a pressure rating ranging from 150 to 2500lbs. We follow standard international and national dimensional standards or any other as per the customer’s request.

We at Shacha Technologies Pvt. Ltd. constantly seek perfection in our practices of administration and production thus making our Global presence felt across 6 continents with number of countries and multiple satisfied customers.